Grease Trap Treatments

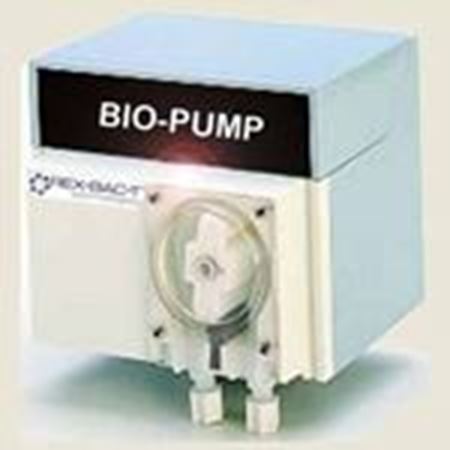

REX-BAC-T Technologies offers a complete line of grease trap maintenance products that are specially formulated for direct addition to Grease Traps and Drains in restaurants, hotels, and commercial buildings. In addition, we design and build grease trap aeration systems to manage the dissolved oxygen (DO) content in the grease trap.

Waste Minimization and Remediation Technologies

- Overview

-

Fats, oils and grease (FOG) in sewer systems are a problem in many cites due to the increase in the number of restaurants. Furthermore, with aging sewer systems in many metropolitan areas, the problem is amplified. By effectively managing the dissolved oxygen (DO) levels and implementing a bioaugmentation program, commercial operations can significantly reduce the FOG that builds up in the grease interceptors (traps). Significant reductions in the soluble BOD and TSS effluent going to the sewage treatment system are the result.

Without the use of a grease trap there, is no simple way to prevent FOG from being carried into the sewer system, wet wells or lift station(s). With proper training of the kitchen personnel, grease trap waste loading can be minimized and will help prevent large quantities of FOG from entering the interceptor and sewer lines.

Federal Document 40 CFR 403.5 regulates and prohibits the introduction of non-biodegradable hydrocarbons into the sewer systems. Limited or no general regulations are in place on other edible cooking fats, oils, or grease, (FOG’s). The regulation of FOG commonly sent to the sewer system is left to the local jurisdiction. The rules are not consistent and are sometimes arbitrary and cumbersome for the restaurant to be in compliance. Furthermore, many local municipalities impose limits that result in surcharges on discharge water to the sewer system.

- Grease Traps (Grease Interceptors)

- Why Manage Dissolved Oxygen (DO) Levels?

- Why Bioaugmentation?

-

Bioaugmentation is the introduction of highly efficient natural microbial strains grown in environmentally controlled fermentation processes that are inoculated into the waste grease interceptor system to treat contaminated wastewater. These highly effective microbes use the simple and complex carbohydrates as a food source yielding water and carbon dioxide. In grease interceptors, bioaugmentation is used to ensure that the in situ microorganisms that are selectively chosen to efficiently degrade or digest the (FOG) contaminating the wastewater maintain the dominant population culture and most efficient microbes.

- Combination of Increased DO and Bioaugmentation Process

- How the Process Really Works…

- Routine Pumping of a Grease Interceptor

- What About Enzymes and Surfactants

- General AeroClear Technology Schematic